DIY Speaker Build

The ShapeOko has been sitting idle for a while, so I decided to take a stab at making my own speakers. I wanted to do something small that I bring outside and hang on my pergola when entertaining guests on our new patio. After perusing the web and checking out some speakers and online enclosure calculators, I landed on a set of HiVi B3N’s (3″) and tweeters. Given that they won’t be permanently mounted outside, I wasn’t too concerned about waterproofing the speakers. Instead, the design is along the lines of water resistance. After doing some calculations on the enclosure size, I threw logic and math out the door and bent the rules by going with a design I had in mind. The volume of this design is not far off from the ideal size, so I expect some sound issues. However, I am counteracting that by using ABS which is strong, and only 9mm thick (so I gain back some lost volume). I also went with a sealed design which I understand is better for when you want to achieve a smaller enclosure…

I wanted to do something small that I bring outside and hang on my pergola when entertaining guests on our new patio. After perusing the web and checking out some speakers and online enclosure calculators, I landed on a set of HiVi B3N’s (3″) and tweeters. Given that they won’t be permanently mounted outside, I wasn’t too concerned about waterproofing the speakers. Instead, the design is along the lines of water resistance. After doing some calculations on the enclosure size, I threw logic and math out the door and bent the rules by going with a design I had in mind. The volume of this design is not far off from the ideal size, so I expect some sound issues. However, I am counteracting that by using ABS which is strong, and only 9mm thick (so I gain back some lost volume). I also went with a sealed design which I understand is better for when you want to achieve a smaller enclosure…

Speaker Enclosure:

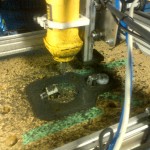

I was toying around with different ideas including using MDF. I wanted to try something different and take advantage of my CNC mill and materials I had laying around. I had some sheets of 9mm ABS that I figured would be worth a try. The thickness makes it rigid enough for an enclosure of this size. If you look at the gallery, you can see the design calls for some angles and rounded corners. I did not want to have to cut individual side pieces to fit each angled edge. Instead, I came up with the idea to form 2 sides for each speaker and join them together later. This required using controlled heat and careful bends for each angle.

I also needed way to ensure that the bends followed the outline of the speaker based on the design. I did this by cutting slots on both the inside faces of the front and back plates. Using a heat gun I applied heat, while bending an angle inserting the speaker along the slot path as I went along. To make sure it worked, I did some test cuts to see if it would work (below). I was pretty happy with the result.

Crossover:

Since the B3N’s are full range speakers, I used a 1st order crossover to cut off highs from the driver so the tweeter could do it’s part. Based on some calculations, a 0.18mH inductor was used for the driver and a 3.9 mfd for the tweeter.

End Result:

|

|

|

|

Build Pics:

Build Materials:

- 1x Abs Outer casing – Milled & custom formed

- 2x Dayton Audio Tweeter (ND16FA-6)

- 2x HiVi B3N Speaker

- 2x Solen Terminals RPT17GAS

- 2x 3.9 mfd 160V Capacitors

- 2x 0.18 mH Inductor

- 1x Grill Cloth

Comments: