DualGrip-NXT Rover

Sometimes I build robots that attempt to solve real world challenges. ![]() Other times, robots are built based on random ideas. This robot is a case of solving a LEGO challenge – specifically, with their Technic tracks/treads #575518. At no fault of theirs, these plastic tracks are slippery on many surfaces. Great for carpets, flat areas, dirt (if you dare) – and great for turning as well. However, when you try to climb with them, they are as slick as ice.

Other times, robots are built based on random ideas. This robot is a case of solving a LEGO challenge – specifically, with their Technic tracks/treads #575518. At no fault of theirs, these plastic tracks are slippery on many surfaces. Great for carpets, flat areas, dirt (if you dare) – and great for turning as well. However, when you try to climb with them, they are as slick as ice.

If you Google them, you will find some great ideas on making these treads more ‘sticky’. Some have used 1/2 Technic pins (which fit nicely into the supplied holes), others have used elastics wrapped around them – all great ideas that work fine. I attacked the challenge from a different angle. The result is DG – or Dual Grip (yes, the name is somewhat plain). DG went through numerous revisions as I worked out kinks related to weight, stability, traction, sensors, flex etc. At the bottom I have included some pictures on previous versions of DG – some changes significant, others subtle.

The idea was to have a treaded robot that could navigate varying terrain, turn quickly and of course, climb. Based on my experience with my other robots using the same tracks (eg UNV and DynaTrax), I found that they were not very good when it came to inclines. I figured that the LEGO rubber wheels have great traction on most surfaces, so why not slap a set of them along with the treads. However, this posed another challenge. I did not want both wheel systems in contact with the ground at all times as this would make turning tougher and be redundant.

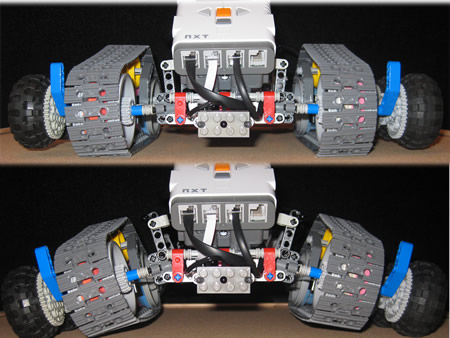

In normal running state, the entire drive system runs parallel to the ground. The wheels do not touch the ground at this point. When the robot meets an incline, the drive wheels are angled down which puts the rubber in contact with the ground. At this point the tracks have little to no contact with the surface. The following set of images shows the two drive states.

I considered creating a dual drive system with rubber wheels and tracks separated by a mechanism that would deploy the rubber wheels downwards when needed. However, after some thinking, I decided on an alternate route. In order to make it easy, light and effective, I figured the most effective way of doing this was to build the rubber wheel drive directly into the tread drive and have the entire structure rotate to change contact points. I am sure there are numerous ways this could be done, but this seemed like the easiest and most obvious approach.

[ad name=”GoogleAS728x90″]

How does it work?

The current version of DG functions in a dual state mode – a combination of both autonomous and remote control activity – all working at the same time. The autonomous portion consists of the NXT brick, a Mindsensors Accelleration Sensor (2 axis2/g), and an NXT motor. The remote portion uses the Power Functions system with a remote control. Its purpose is to drive and steer. When running, the NXT is monitoring the robot via the Mindsensors Accelleration Sensor and can detect when DG is beginning a climb. When it detects a certain (consistent) level of G’s, it triggers the NXT motor to deploy causing both sets of track/wheel combos to angle themselves. This results in the wheels making contact with the ground, and the treads loosing contact (more grip). When the robot reaches level ground, it reverses and returns the tracks to level.

That is cool!!

I understand this is in response to a LEGO challenge. But if you add the rubber tires to the side, what is the point of still having tracks? I mean, is there any situation where tracks would work better than the 6 wheels on the sides? Otherwise, I’d just make a robot with the 6 wheels, and get rid of the tracks altogether 🙂

@santi: In answering your below question – Yes, there is at least one situation where tracks would work better than wheels alone. I challenge you to build two similar robots (same size and wheel widths as DualGrip) – one with tracks and the other with 6 wheels as I have built it. Then, take those two robots and drive them on carpet making sure you try to do quick sharp turns in the process. Tell us which one turns faster without catching or buckling in the carpet? I am sure your answer will be the tracked robot is faster. Hence the reason for my challenge. Tracked robots are great for navigating all terrains. Tires can also meet these needs if you place the tires close together and your robot is not too wide. However, if you place a number of rubber wheels far from the center turning radius, you will see what I am talking about – they grab and bind while turning – especially on carpet.

If the LEGO tracks had rubber gromments in them, then I would not have been writing this as there would be no challenge and no robot to build. However, LEGO tracks are quite slippery on most smooth/hard surfaces. Rubber wheels satisfy the grip and climbing aspect, while the tracks satisfy the general turning and quick maneuverability requirements. Make sense?

Looking closely at your design, is the NXT also controlling the power-functions motor? how do you do that!?!? is it possible to generate an infra-red signal from the NXT to control the power-functions motor?

Yes, that is correct. If you read the “How Does it Work” section, I describe it in more detail there. Essentially, I am driving the robot FW/REV while the NXT and accelleration sensor determines the slope and causes the tracks to contract/expand automatically.

I was wondering the same thing about the wheels for climbing and tracks for driving. I would think it would be the other way around. Wheels for speed on the ground and then tracks for climbing hard obsticles where the tires might get stuck.

I do see where tracks would help on a 360 spin, where tires would need to take a big circle turn if you have room. (side note: discovery had a tank build off, one team used full tracks second team used small tracks with wheels in front. the tank track style could not 180 spin where the small track with wheels took less time. I think bad track design on the first teams part. But it was intresting to see it have such a hard time turning in dirt.)

Maybe a 4 wheel steering design would make turning easier and still be able to climb and move fast.

Thx for the comments. What you are saying would be true in a real-life setup. However, if you have these LEGO tracks, you will find that they are hard smooth plastic and have little to no grip on many surfaces (especially tile / hardwood). So, in LEGO reality, the tracks are better for quick turns etc, and rubber tires for climbing as they have sticking power.